Max Color

MaxColor is an award-winning set of colour conversion tools which has been specifically developed to meet the requirements of the Packaging sector.

The resultant print uses less ink, with more vibrant colours and a better quality registration whether printing Flexo, UV Offset or Gravure.

Colour conversion for packaging print

MaxColor utilizes CMYK or RGB Tiff files for image conversion, or MaxPro files for image and linework conversion.

The intuitive interface within MaxColor allows for the generation of Multi colour separations, whilst providing tools for post conversion tonal adjustments and selective colour editing.

Reducing print separations or converting CMYK separations to spot colours, means less ink usage, more vibrant colors and better registration.

Utilizing MaxColor enables Brand owners, Prepress houses and Printers to take advantage of the benefits associated with printing with an expanded colour gamut.

Colour filters

Colour shade libraries or individual colours can be introduced into MaxColor via look up tables, spectrophotometer readings or by entering pre-defined values.

An internal colour engine analyzes the individual ink characteristics and also the relationship between the relevant colour separations.

MaxColor then calculates the overlap appearance when the selected colours are combined and creates a bespoke colour filter which is stored in a central database.

These colour filters are applied to image or image and text combinations – The result is a colour converted file which accurately displays the new colours on-screen.

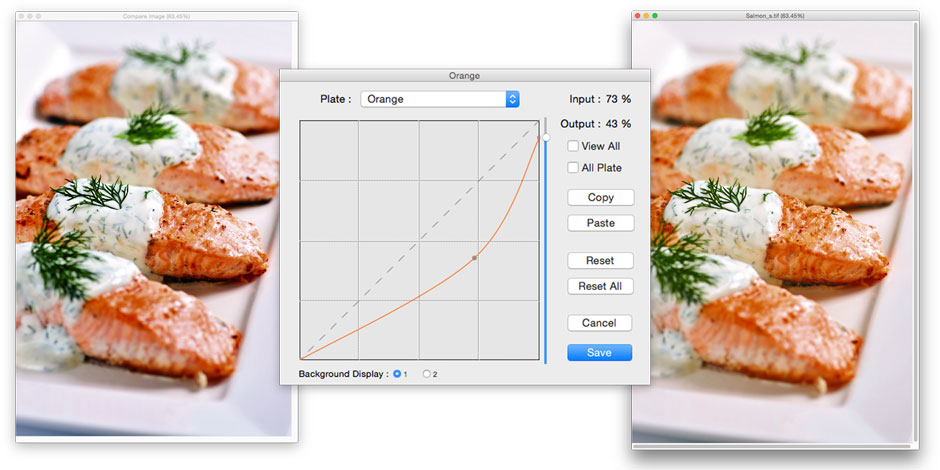

Tonal adjustments

MaxColor also has it’s own internal monitor calibration system which has been specifically developed to more faithfully reproduce spot colour rendition on-screen. When compared to alternative image editing applications, MaxColor delivers a superior representation of spot colour overlap appearance in images.

Once the colour filter is applied, MaxColor provides tools to allow tonal adjustments, selective editing or image masking. A colour comparison window allows for a visual before/after view, whilst colour adjustments can be monitored via a colour meter.

Selective editing and masking

When using non CMYK colours within images, MaxColor brings further benefits by allowing users to edit selective areas where a more vibrant effect is desired.

This allows Brand owners, Prepress houses and Printers to take full advantage of the vivid colours available when printing with spot colours – creating a tailor-made image which is virtually impossible to recreate using CMYK inks sets.

A masking feature enables users to further enhance specific areas of an image. This gives users the ability to apply colour conversions and adjustments to the overall image or just the masked areas.

Winner of the 2011 FlexoTech Innovation in Prepress

What the Judges said:

‘The winner is an innovation that clearly moves the game on, with far reaching potential in several aspects of flexo printing. Its commercial benefits are matched by environmental improvements, which all add up to greater efficiency and higher productivity without any loss of print quality. It offers reductions in ink and substrate consumption, the use of fewer plates, and allows jobs to be produced by fewer print units that consume less energy – in a nutshell, it is hard to see a downside – great innovation!’